Comparision of Shape Memory Alloy Connections

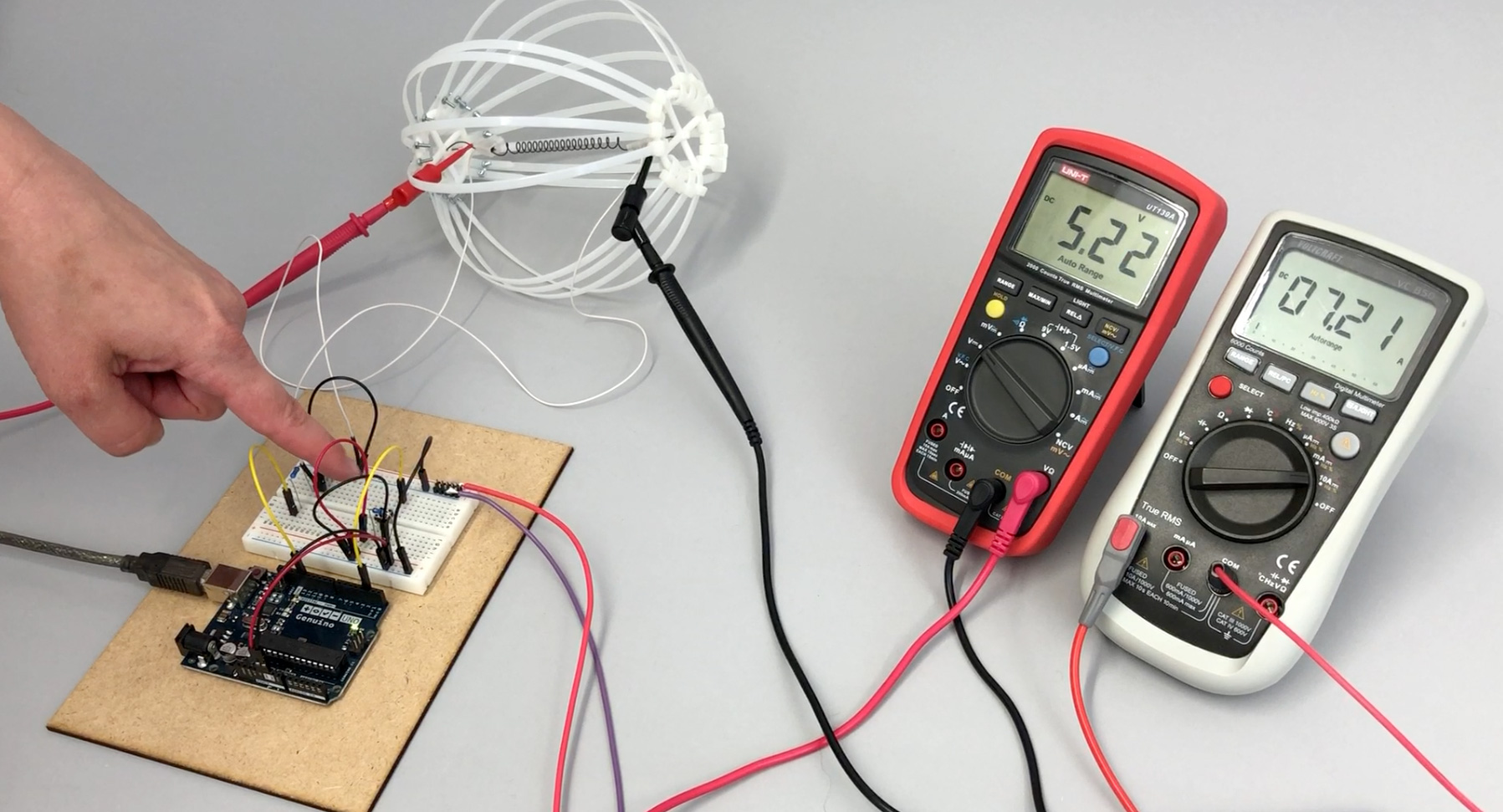

Shape memory alloy (SMA) is a commonly used actuator for creating silent shape-changing interfaces. In this project, we compared two different SMA connections (e.g., alligator clips and screw-terminals) and measurered the resistance. To this end, we used a breadboard assembly with a stabilised 9V supply to activate the two SMA spring systems. The SMA alligator clip system measured a voltage of 3.35V with a current of 4.47A, and the SMA screw-terminal system measured a voltage of 5.22V with a current of 7.21A. In conclusion, the SMA screw-terminal system provided a lower contact resistance and demonstrated a faster movement.

Electrical Background

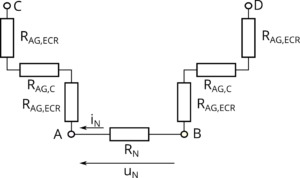

Typically, the resistance of the mayor components in an electrical circuit is orders of magnitudes higher than the resistance of cable and contacts, so they are neglected. Here, the resistance of the main component, the shape memory alloy, is in the order of the cable and contact resistance so they need consideration.

The alligator clips have contact at the points A and B with the shape memory alloy. On the other end, again an alligator clip provides the contact to the stabilised power supply at the points C and D. The contact area of the alligator clip with the shape memory alloy wire is tiny, sometimes only the tip of the tooth.

We measured for the alligator clip system only a voltage of uN = 3.35 V with a current of iN=4.47 A through the shape memory alloy. Hence, the shape memory alloy is powered with approx. 15 W and has a resistance of RN=0.75 Ohm.

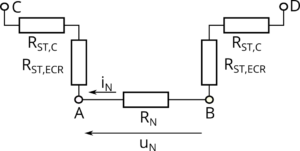

In comparison, the screw-terminals have contact at the points A and B with the shape memory alloy. On the other end, the supply wires are directly connected with the bread board. As this contact is approximately the same as with the alligator clip setup, so it can be omitted.

The electrical contact resistance of the screw-terminal is more complex than the alligator clips. Within the housing, the electrical housing, the screw, the shape memory alloy and the cable have contact with each other. Hence, multiple contact-resistances are in parallel, which reduces the total contact resistance of the screw-terminal.

For the screw-terminal system, we measured a voltage of uN = 5.4 V with a current of iN=7.21 A. The shape memory alloy is powered with approx. 39 W and has again a resistance of RN=0.75 Ohm.

The different setups have no influence on the resistance of the shape memory alloy, it is the same in both cases. The voltage drop from the power supply to the shape memory alloy is roughly 2 V less in the screw-terminal system as in the alligator clip system. This leads to a higher current trough the shape memory alloy and approximately doubles the applied power and hence leads to a faster movement.

SMA alligator clip system

SMA screw-terminal system

People

Jessica Broscheit

Thomas Lehmann

Professor für Programmierung verteilter technischer Anwendungen